Application of dry fog dust suppression device in air dust removal in port area

Zhang Yu

(Qinhuangdao Port Co., LTD., Qinhuangdao 066000, China)

Compared with the traditional dry dust collection mode, the dry fog dust suppression device used at the dump and transfer tower at the current port area can not only save water consumption and energy loss, but also eliminate dust particles below 10 microns through the contact, aggregation, adsorption and condensation of water mist with fine dust. Avoid the waste that causes secondary pollution to the atmosphere during the operation of the dry fog dust suppression device. Based on this, it is very important to explore the application of dry fog dust suppressant device in atmospheric dust removal in port area.

1. Project overview

The project of air dust removal in a port area is coal dust control in coal port, which mainly applies dry fog dust suppression device in the tipper and transfer tower. The process flow is as follows: coal transportation and train entry into port - dump machine operation - belt conveyor transfer - transfer tower - belt conveyor transfer - stacker operation - storage yard temporary - retainer operation - belt conveyor - transfer tower - belt conveyor - loading machine - loading away.

2. Influence of atmospheric particulate matter

Atmospheric particulate matter is the main factor affecting the quality of atmospheric environment in the port area, especially in the near-ground environment of the port area (around the height of human breathing belt), the concentration of dust particulate matter has an important impact on the health of people in the port area and surrounding area. In addition, atmospheric particles can reflect and absorb solar radiation, increase earth surface temperature and reduce regional environmental visibility.

3. Status quo of atmospheric environment in port area

At present, in the process of coal loading and unloading in the port area, the dumper and transfer tower are in closed state. The belt conveyor is equipped with the dust cover of the belt conveyor and is at the transfer point

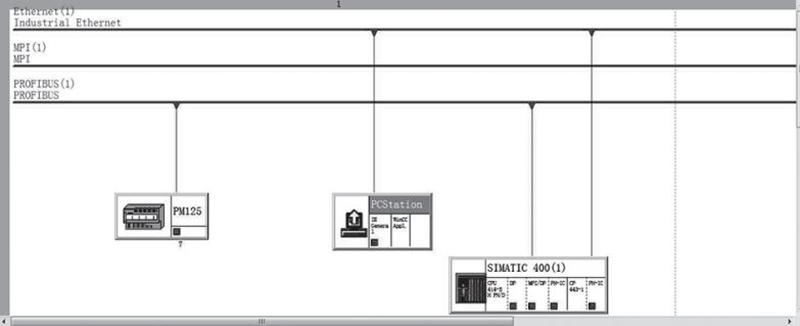

Figure 6 NetPro network structure diagram

FIG. 7 Control curve

Phenomenon, so the use of temperature cascade control system. Each reaction tank is a wide in the middle, narrow up and down the structure, the change of water level and flow is a nonlinear structure, the liquid level is close to 50%, the greater the inertia. It's much more linear. And its safety index is also around 50%, too high and easy to overflow, too low and easy to dry burn, will cause damage. The basic method is to control the liquid level by adjusting the water inlet valve. At the same time, in order to prevent the fluctuation of the flow during the adjustment of the liquid level and increase the disturbance of other links, the cascade control of the flow level is a very effective method. It can be seen from the running results that the control system based on PCS7 has high control precision, good stability and strong anti-interference ability.

Installation of dust removal equipment, construction of windproof dust suppression net around the yard, and equipped with sprinkler system, to prevent dust discharge to a great extent. In recent years, the port has continuously improved its dust pollution control system, and promoted the project of dry fog dust suppression system for dumpers and transfer towers to improve the environmental quality of the port and surrounding areas.

Reference literature

[1] Du Qingqing Design of Continuous Process Control System Based on SMPT-1000 Experimental Platform. Journal of Lanzhou Petrochemical Vocational and Technical College,2019,1903):21-25

[2] Li Haixia, Du Qingqing. Design of multi-vessel Control system based on SMPT-1000 and PCS7 [J] Automation in Petrochemical Industry,2019,5503)2-25

[3] Wang Hao, Wu Feng, Zhang Jianqiang, Li Wenyang. Continuous process control of PVC industrial Reaction based on PCS7. Automation and Instrumentation,2018,3(10):33-36

[4] Song Yuqin, Li Chao, Cheng Cheng, Zhao Yang. Design Automation Technology and Application of integrated control system of Chemical reaction Kettle based on SIMATC PCS7,2018,3705)9-13

[5] Gao Qing, Zhang Li, Gao Tiantian, Xue Xulu. PI Parameter Setting and Analysis of Temperature Control System of Reaction Kettle Based on PCS7 [J] Computer and Digital Engineering 201745(08):1607-1610+1624

[6] Yuan Wenqiang. Research and Implementation of Superheated Steam Temperature Control in Boiler [D]. Northeastern University 2017

[7] Ma Liming, Bai Rui, Gao Tiansheng. Industrial continuous reaction process control based on PCS7

Design and Development of System [J], Journal of Liaoning University of Technology (Natural Science Edition), 2016,36(05):286-290+295

[8] Ma Zeyu, Li Ji. Design of Small Reactor Control System Based on Fuzzy-PID [J] Automation Technology and Application, 2013,32 (12) : 29-34

4. Application of dry fog dust suppression device in atmospheric dust removal in port area

4.1 Dry fog dust suppression and dry fog particles

Dust particles less than 150Lm (especially inhalable dust particles with diameter less than 10Lm) are mainly treated by dry fog dust suppression device in the position of dumper and transfer tower. Although dust particles below 150Lm account for less than 1.0% of the total material, it poses a great threat to human health and life, and is also the main source of occupational diseases such as silicosis. This is mainly because dust can be bonded gradually by water (or chemical agents), and fine dust can not break through the surface tension of water condensation when the water drop is larger. The dry fog dust suppression device mainly uses water mist particles whose size is close to that of dust particles to promote them to contact, collide, bond and polymerize with water mist particles in the process of moving with air flow, and land when the dust mass reaches a certain mass. The dry fog dust suppression device used in the atmospheric dust removal project of coal port area can produce water mist particles with a diameter of 1~10Lm, effectively adsorb the dust suspended in the air, especially the inhalable particles with a diameter of less than 10Lm, and promote the fine dust to settle under the action of gravity, so as to achieve the purpose of dry fog dust suppression.

In the air dust removal project of coal port area, the dry fog particles are mainly generated at the receiving point of the dumper and the dumping position at the head of the transfer tower. The former is mainly after the material falls into the belt with the tipper, because the falling material will release a large amount of potential energy, which can cause the dry fog particles produced by the dry fog dust suppression device and the subsequent falling material to continuously collide and condense, so as to achieve the purpose of dust; The latter is mainly when the material falls into the downstream along with the head of the converter tower. Due to the potential energy released by the falling material, the material bounces back on the surface of the throwing spoon at the head of the converter tower, contacts, aggregates and condenses with the subsequent dust particles, and then falls into the cabin.

4.2 Specific Application Devices

The dry fog dust suppression device used in the atmospheric dust removal project of coal port area mainly adopts modular design technology, including multi-functional system, screw air compressor, micron level dry fog machine, electronic control system, water-gas connection pipeline, spray assembly (including universal joint spray assembly), automatic control system, electric heat tracing system and other parts. Among them, the multifunctional system integrates the water gas regulating valve, electromagnetic control valve, filter, pipeline purging valve, pressure sensor (hot dip zinc tube), can filter the suspended matter in the water of the external water source, and promote it to meet the requirements of the sprayer assembly (including universal joint sprayer assembly). And distribute the adjusted air and water to each sprayer assembly through the distributor and valve; Screw air compressor with capacity control valve, can provide standard gas source for micron level fog machine; Micron level dry fog machine includes multifunctional control system, electronic control system, flow control system and other parts, mainly installed in the inlet and outlet pipe interface, inlet and outlet pipe interface standard body, responsible for the water, gas filtration, in the pre-set gas flow, water pressure, gas pressure environment, through the switch program, start the solenoid valve, or close the solenoid valve. The electronic control system is the core of the dry fog dust control device used in the atmospheric dust removal project of coal port area, including relay, protection circuit, programmable controller and several components, with two modes of automatic control and manual control. Among them, automatic control is mainly to automatically receive remote signals with countries to start, or shut down the sprayer. Manual control means that the operator starts or shuts down the sprayer through manual operation. The water-air connection pipeline is responsible for connecting the compressed air storage tank, micron dry fog machine, atomizer assembly (including universal joint atomizer assembly), water source, etc., to ensure the smooth operation of the dry fog dust suppression device used in the atmospheric dust removal project of coal port area. The sprayer assembly (including universal joint sprayer assembly) is mainly responsible for receiving gas and water transported by micron level dry fog machine, and converting them into dry fog particles with a diameter of 1-10.0 micron according to the instructions of the electronic control system, which are sprayed to the corresponding dust points. The automatic control system is through the PLC platform, the micron level dry fog machine, the field equipment control signal is effectively connected to realize automatic control; Electric heat tracing and insulation are mainly distributed in key modules of dry fog dust suppression devices used in atmospheric dust removal projects in coal port areas, such as micron level dry fog machines, sprayer assemblies (including universal joint sprayer assemblies), gas pipelines, water pipes, etc., which can raise the ambient temperature when the temperature is below +5.0℃.

4.3 Application effect evaluation

The dry fog dust suppression device used in the regional air dust removal projects of coal ports has successfully filled the gaps in technology, production and application of such equipment in our country, improved the automation level of environmental protection in coal ports, reduced the dust pollution to the atmosphere in coal ports, improved the surrounding environment of coal ports, and reduced the probability of occupational diseases among on-site operators. It has outstanding economic and social benefits.

Firstly, the dry fog dust suppression device used in the air dust removal project of coal port area has excellent dust suppression ability, which reduces the amount of coal loss. Each tipper can reduce the economic loss of coal by more than one million yuan every year. Traditional dust removal equipment, mainly operated on the principle of negative pressure, will lose a lot of heat in the port area, increasing the heating cost. Compared with traditional dust suppression device, dry fog dust suppression device consumes less water and has less calorific value loss, which can avoid coal calorific value loss. Since the water content of the material hardly increases, the probability of two pollution problems can also be reduced after the application of dry fog dust suppression device.

Secondly, due to the application of dry fog dust suppression device in the air dust removal project of coal port area, there is no need to clean the coal pool frequently, which reduces the labor cost of cleaning the dump room unloading coal pool and controls the labor cost. At the same time, micron level dry fog dust suppression device in the cold weather season (below the freezing point in winter) more prominent fine dust adsorption and settlement capacity, can improve the means of port dust removal. In addition, the dry fog dust suppression device used in the air dust removal project in coal port area can control the dust explosion risk accident by reducing dust concentration and detonation temperature.

Then, compared with the traditional dust removal device, the dry fog dust suppression device used in the atmospheric dust removal project of coal port area can carry out dust control at the source of the pollution, and has a better effect on the control of inhalable dust below 10Lm. At the same time, the overall dry fog dust suppression device equipment input is less, and its internal electronic control system, automatic control system and multifunctional system Settings, can realize all aspects of automatic control, more convenient operation, small footprint, low operating costs.

conclusion

In summary, dry fog dust suppression device has outstanding advantages in port area air dust removal project, but it is still in the stage of application and promotion at present. Therefore, in order to give full play to the advantages of dry fog dust suppressant devices in water saving, energy saving and secondary pollution prevention in the control of inhalable dust less than 10 microns in the port area, the port area, especially the coal port area, can prioritize the use of dry fog dust suppressant devices with excellent environmental performance and effective energy saving and related equipment to reduce the atmospheric particulate matter content in the port area. To ensure the ecological environment quality of the port area.

References:

[1] Zhang Yan. Report on the conditioning of coal unloading storage system and dry fog dust suppression device at the Port of Huanghua. Science and Technology Innovation and Application,2019(6):58-60

[2] Wang Yanan, Wang Haiyan, GAO Jingru. Application of micron level dry fog dust suppression technology in train double-car Tipper system Shandong Coal Science and Technology,2018(6):185-186

[3] Meng Xiaojuan, Guo Chengtao. Shandong Coal Science and Technology,2018(5):198-199

| Previous:Application and reformation of dry fog dust suppression technology | Next:Application and reformation of dry fog dust suppression technology |

TEL

TEL

PRODUCTS

PRODUCTS

SOLUTION

SOLUTION

CONTACT

CONTACT